What's been happening in the world of health and safety recently? Here are four top stories from the last 7 days:

Doncaster dig scuppered by asbestos particles

Archaeology enthusiasts in Doncaster were left disappointed this week when asbestos particles were found in soil samples outside St Peter in Chains Church on Chequer Road. This location had been chosen as the site for a dig to "uncover the borough's First World War heritage", but work was halted as soon as those overseeing the dig suspected that potentially harmful debris might be present under the ground. The trenches have now been filled back in.

See also: #BewareAsbestos with Label Source

Aberdeen council fined after near-drowning incident

Aberdeen and Aberdeenshire councils were both hit with hefty fines this week in relation to an incident that occurred in 2012. An 11-year-old boy narrowly avoided death after being found unconscious under the water at Stonehaven outdoor pool; a court found that both the number and positioning of lifeguards at the pool had been insufficient, and the two councils have been fined £9,000 (Aberdeen council) and £4,000 (Aberdeenshire council) for failing to carry out a sufficient risk assessment.

See also: Hazards from Recreational Water-Based Activities

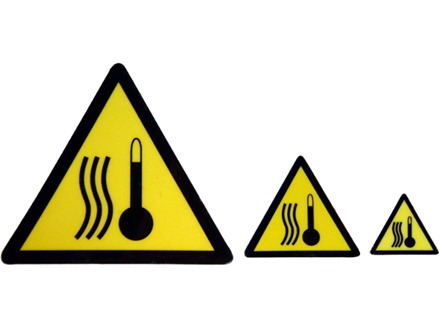

Bruton sculpture too hot to handle

A bronze sculpture in Bruton, Somerset, is to be fitted with a hazard warning sign to remind passers-by that the sculpture's surface can get very hot on sunny days. Man on a Bench by Giles Penny is a popular landmark in Bruton, but the town's mayor is concerned that visitors who sit on the sculpture for a photo opportunity may get a "shock" if the metal has been heated by the sunshine.

See also: Hot Surface Signs & Labels

Warning signs torn down at lake where teenagers drowned

Two teenagers drowned in the Thorpe St Andrew lake in Norfolk this Wednesday, and local news outlets have reported that safety signs placed around the area in question had been vandalised prior to the incident. A representative from the Norfolk Wildlife Trust - who run the site - expressed frustration over failed attempts to warn swimmers of the hazards and discourage them from entering the water. "We put signs up, but they have all been torn down or vandalised," said Brendan Joyce, the Trust's CE. "There were half a dozen signs at key points so there was no way they could have been overlooked."

See also: Cambridgeshire Policeman Highlights the Importance of Water Safety Signs

More health and safety news and insight here >>

Pictured (left to right): St Peter in Chains Church, Doncaster; Stonehaven outdoor pool, Aberdeenshire; Giles Penny's Man on a Bench, Bruton

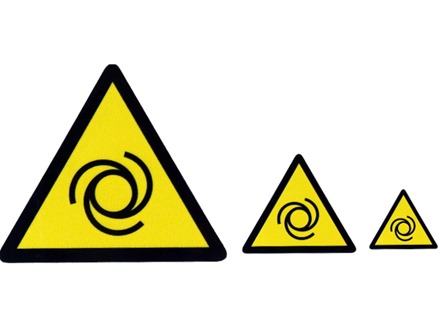

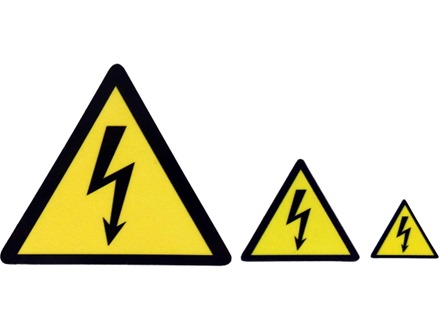

You probably see warning symbols like the ones pictured above practically every day. Granted, some people - such as those who work in labs or hospitals - will see them more often than others, but even if your job seldom exposes you to hazardous substances and situations, it's still important to know what these symbols mean. You never know when that knowledge might come in handy!

So how well do you know your warning symbols? Below, you'll find 10 standard warning symbols (all of which can be found in our Warning Symbol Labels department) - all you have to do is name the hazard that each symbol identifies. We bet you can't get them all!

1) Can you guess what this big black cross means? Click here to find out!

2) This warning symbol is commonly seen in certain films and video games - if you don't already know what it means, find out here!

3) Come on - this one's easy, right? Answer here.

3) Reckon you know what this warning symbol means? Click here to find out whether or not you're correct.

4) Exploding hot dogs? Something to do with cricket bats? Find out the true meaning of this symbol here.

5) Three wavy lines. What are they warning us about? Find out here.

6) Right, we've been going easy on you so far. Here's a tricky one - find out what it means here!

7) Confused? Click here to learn the meaning behind this assemblage of lines, arrows and fingers.

8) Slightly easier, this one - you've almost certainly seen it before, but what does it mean? Find out here.

9) More wavy lines! What do they mean? Answer here.

10) We'll end with a nice easy one. We're really hoping you know what this means - check your answer here!

So...how did you do?

0-3 points: Oh dear! Perhaps you need a warning symbol of your own?

4-7 points: Must try harder!

8-9 points: Good work!

10 points: Safety superstar!

Need to brush up your knowledge? Head over to our Warning Symbols department and do some revision for next time!

Most people would agree that safety signs play a critical role in our society. By clearly identifying potential hazards and warning people of danger, signs prevent injuries and fatalities very effectively - it's impossible to calculate how many lives have been saved by health and safety signage.

Still, there is one problem with standard signage that the health and safety industry has yet to properly solve: over-familiarity. We see safety signs practically everywhere we go, and this seems to sharply reduce the impact of those signs.

This issue is most pronounced on our motorways - how often have you ignored or failed to spot a road safety sign whilst driving? - but it's actually present right across the board. From PPE notices on construction sites to the 'Deep Water' and 'Sudden Drop' signs that are still being vandalised throughout the UK, safety signs have become part of the general landscape, and their important information is all too often going unheeded.

So how can this problem be tackled? Many people seem to think that the answer is to use humorous and/or emotive signs that will grab people's attention. One example is the city of Laredo in Texas, USA; the Texas Department of Transportation recently installed a series of comically oversized road signs in the city, complete with such slogans as "Give Us A BRAKE" and "REALLY - STOP MEANS STOP". According to one traffic safety specialist, these 15-foot monstrosities have been erected in the hope that drivers will be encouraged to "be safe", "read the signs", and "focus on the road".

This sort of thing is happening here in Britain, too, although we're taking a slightly different approach:

The sign in the photo above is currently isntalled on a road in Cheshire, and this emotive approach - encouraging motorists to think of the lives they may affect with unsafe driving - is "thought to have led to lower speeds" according to ITV.com

So is it time for novel ideas like these to be implemented everywhere? Perhaps, although it's important to remember that standard safety signs are still very much essential. We at Label Source feel that the best way to use these funny and emotive signs is in conjunction with regular signage; this will ensure that all the essential information is clearly provided even as we attempt to capture imaginations and tug at heartstrings.

See also: French village deploys dark humour to promote road safety

Our metal nameplates and tags come in a variety of different materials, including brass, steel, and anodised aluminium. This variety is important to us - we take great pride in providing a labelling solution for any requirements, and by stocking several different metals, we are able to cater to a far wider range of customers than most other suppliers.

Today, however, we'd like to focus on one material in particular: stainless steel. While it's not the perfect choice for every situation - if it were, we wouldn't stock those other options mentioned above - we do feel that it's a very versatile option that's very well-suited to most applications. Here are a few reasons to choose stainless steel for your tags and nameplates:

- Made of 316 marine grade stainless steel

- Resistant to stains and chemicals

- Suitable for use in extreme temperatures

- Ideal for salt water environments

- Suitable for marking valves, pipes, tools and plant

- Supplied in 304 grade stainless steel

- 0.5mm thick (24 swg)

- Chemical- and stain-resistant

- Suitable for a wide range of temperatures

- Available in a variety of sizes

- Able to be sterilised

- Equipped with drill holes and self-adhesive backing for easy fixing

- Ideal for the labelling of equipment and machinery

Visit our Metal Nameplates and Metal Tags pages to see more of Label Source's range.

PPE (Personal Protective Equipment) is a crucial consideration in many different industries. Doctors (who are frequently at risk of infection) and builders (who face any number of hazards over the course of a working day) are obvious examples, but PPE isn't just something for the medical and construction industries to worry about - protective equipment is used practically everywhere, from fire and police stations to warehouses and post offices.

Sadly, the requirement for PPE is one that's all too often forgotten by employers and their staff. It's easy to dismiss protective equipment as yet more 'red tape' that gets in the way of one's job, but the truth of the matter is that PPE saves lives - without it, your employees are at risk, and you and your business are liable for any damages.

Here are some sobering case studies from a variety of different industries:

Nurse sues hospital company after contracting Ebola

If Nina Pham's name sounds familiar to you, it's probably because her story was one of the biggest of last year's Ebola outbreak. Ms Pham was the first person to contract the disease on American soil, and though she fortunately recovered the illness, she has since filed a lawsuit against her employer, Texas Health Resources, on the grounds that they didn't to enough to protect her from infection. The lawsuit states that the company did not adequately train employees to avoid exposure; furthermore, they did not provide the correct protective equipment, which meant that Nina Pham's neck and hair were exposed whilst treating an infected patient.

Worker paralysed after three-metre fall

A 34-year-old man named Colin Shields was left paralysed from the neck down after suffering a fall at work. Mr Shields fell 3 metres from the top of a gritter; the Health & Safety Executive fined his employer, Inex Works Ltd, £13,500 for breaching the Work at Height Regulations 2005. A press release on the HSE website suggested that Mr Shields ought to have been "wearing a harness or restriant to protect him from falling".

Narrow escape for man hit by falling guttering

Valentin Taljanov (aged 61 at the time of the incident in question) was seriously injured after a piece of cast iron guttering fell onto him at Aberdeen Harbour, where he was working at the time. Mr Taljanov suffered a broken arm, a punctured lung, and multiple other injuries, although the damage could potentially have been even worse; an HSE press release stated that "it was probably only Mr Taljanov's hard hat that prevented him from being killed".

Hopefully, these three stories have more than convinced you of the importance of PPE. If you are an employer, be sure to train your workers properly, and put up the proper PPE signs to remind them of their responsibilities at all times!