PAT test labels are a common sight in workplaces across the world. They’re found on all types of appliances, from microwaves to computers to fridges. If it’s an appliance, then it needs to be PAT tested.

If appliances aren’t tested, the employer will be liable if they malfunction. While it doesn’t take long to do, a PAT test is the foundation of a robust safety strategy in all workplaces.

Below, we explain how to do a PAT test, what the UK’s PAT testing regulations are, and what a PAT test actually is.

What is a PAT Test?

PAT stands for Portable Appliance Testing. These tests ensure electrical appliances are safe to use in the workplace.

A PAT test consists of two stages: a visual inspection and a deeper review using specialised equipment. In total, a PAT test looks at:

- Insulation resistance

- Earth continuity

- Lead polarity

As you can probably tell from this list, a professional must conduct a PAT test. A member of staff can conduct the visual part of the test, but you will need a certified electrician to do the full PAT test.

PAT testing is mandated by The Electricity at Work Regulations 1989. This law does not make a the test a legal requirement, but it does maintain that electrical appliances should be kept in a safe condition.

To do that to an adequate level, businesses must set up regular PAT testing for their appliances. Grading appliances using the following three metrics calculate how often they should be tested:

- Risk level

- Electrical class

- Appliance category

Factors like age, frequency of use and the appliance’s history are very important too. So, if an appliance is medium risk, in an important electrical class and is an essential appliance, then it should be tested every six months.

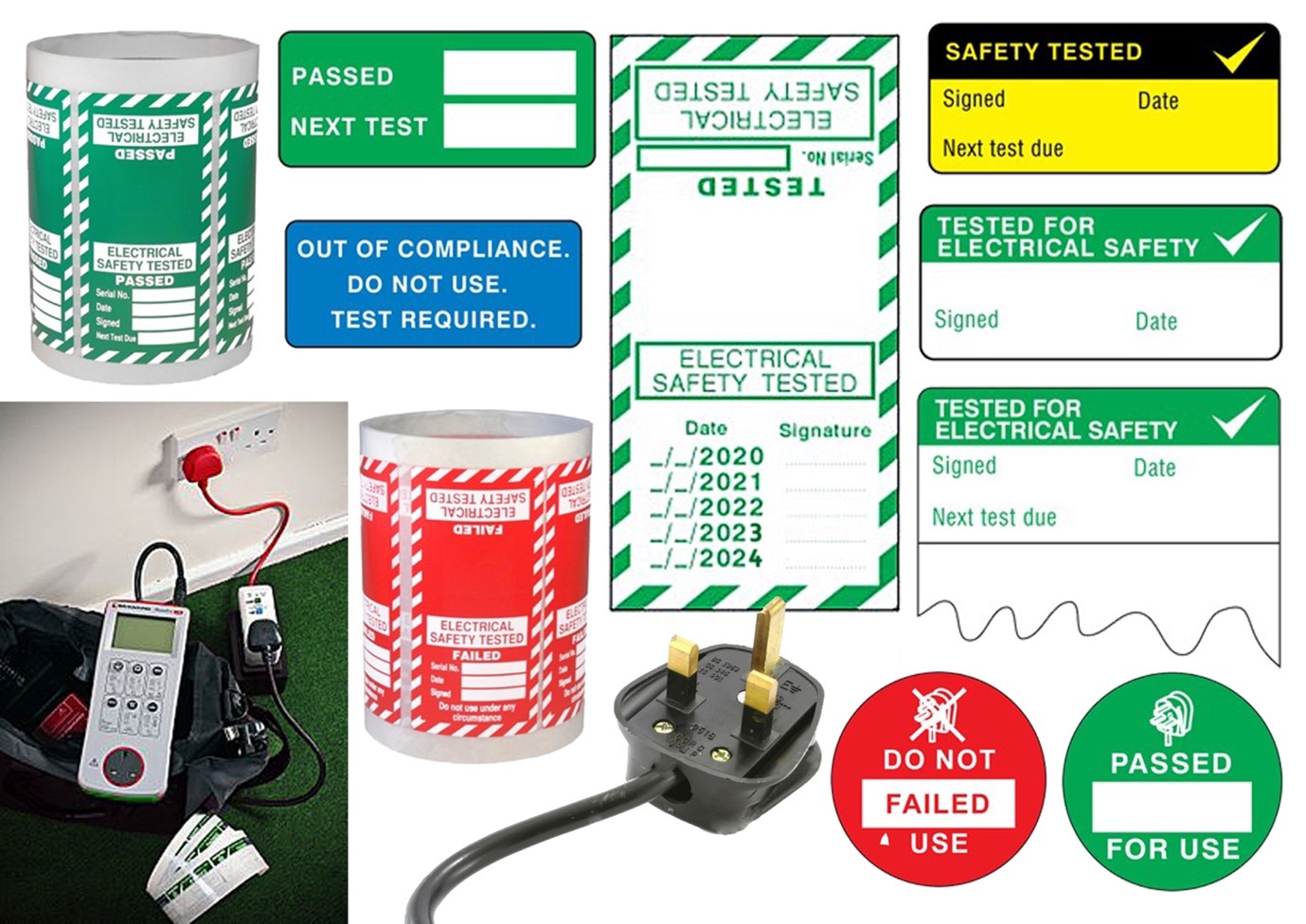

It is not a legal requirement to label equipment with a PAT test label, but it does help with organising tested appliances.

How to Do a PAT Test

To conduct a PAT test, it is recommended that you attend a PAT testing course and hold a PAT testing certificate. Even if you’re handy with electronics, lacking this information and documentation is a big risk.

The only piece of equipment you need to conduct a PAT test is a PAT tester. There are many models available on the market, and if you’re a business who needs these tests, it’s worth investing in one.

Simply plug the electrical appliance into the PAT tester, and press the appropriate button depending on the appliance class. So, if it’s a class one appliance, you would press the class one button.

This will then give three readings: one for insulation resistance, one for earth continuity and one for lead polarity. It will then provide a pass or fail grade.

It is then essential for the tester to log the results in an equipment test record log. This should contain all visual information about the appliance and the readings given by the PAT tester.

Of course, as an extra layer of protection, you should make sure to add a PAT test label to the equipment. Labels are an effective contingency if the equipment test log is lost or destroyed.

Get Your PAT Test Labels Today

If you are due a PAT test, then stock up with some high-quality PAT test labels today.

Known for producing reliable labels with fast shipping, Label Source won’t leave you disappointed.