Label Source supply a wide range of standard design write and seal labels. These labels are alternately known as self laminating labels, write and mark labels, or flap labels.

These write and seal stickers consist of a two part construction. A print receptive base substrate material, such as self adhesive vinyl, has a part attached clear protective laminate. The laminate has a flap, with a backing release paper. Handwritten information can be added by ball point or marker pens. The flap backing paper is removed, and the clear film seals the total label surface. The self adhesive label or sticker is abrasion or scratch resistant, chemical resistant (including oils and solvents), waterproof and weatherproof. These labels are rub test compliant.

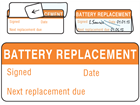

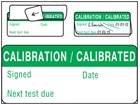

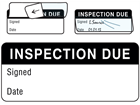

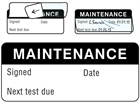

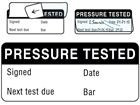

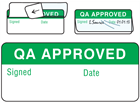

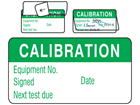

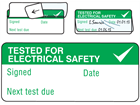

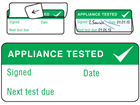

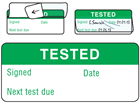

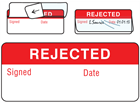

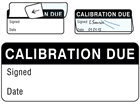

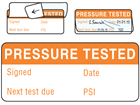

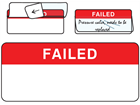

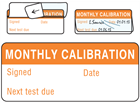

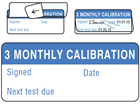

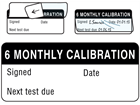

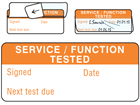

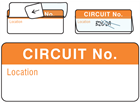

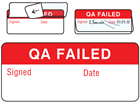

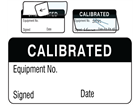

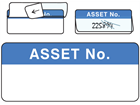

Applications for these labels include PAT and electrical testing, inspection, identification, equipment numbering, maintenance, servicing, pressure testing, product tests, qualty assurance, calibration and safety checks.

Markets for write and seal labels include; electrical inspection; hospitals and medical use; research and development laboratories; defence; marine; aerospace; pharmaceutical; chemical; automotive; and engineering.

Jumbo size write and seal labels for larger equipment are available. Also bespoke self laminating labelscan be personalised to customer specification, even in small to medium quantities,

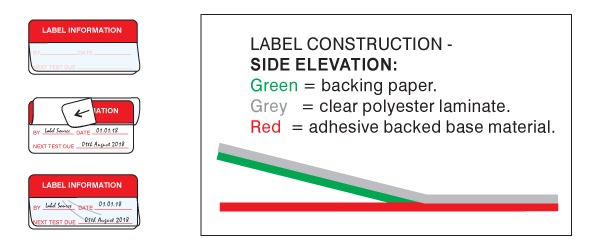

Write and Seal Label Construction

The label supplied comes with a two part construction, base material and surface laminate. The clear laminate supplied attached to the top section of the base material. Remaining laminate has backing paper to prevent adhesion until removal.

The label supplied comes with a two part construction, base material and surface laminate. The clear laminate supplied attached to the top section of the base material. Remaining laminate has backing paper to prevent adhesion until removal.

Add written details as require, then remove backing paper on the laminate.

On removal of backing paper, press the laminate firmly onto the base material to seal in the written information.

The label supplied comes with a two part construction, base material and surface laminate. The clear laminate supplied attached to the top section of the base material. Remaining laminate has backing paper to prevent adhesion until removal.

The label supplied comes with a two part construction, base material and surface laminate. The clear laminate supplied attached to the top section of the base material. Remaining laminate has backing paper to prevent adhesion until removal.